Henan Doing Machinery provides a range of palm oil making machines to extract oil from fresh fruit bunches of oil palm. The following is the typical palm oil manufacturing process which might be useful for new investors of palm oil production business.

|

| Palm oil making machine |

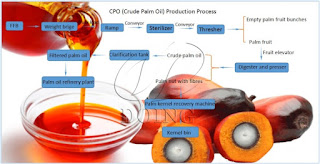

The manufacture of crude palm oil involves a series of processes starting with harvesting fresh fruit bunches from the plantations and ending with crude palm oil storage. Through sterilizing, threshing, digesting and expelling, crude palm oil will be pressed out in palm oil pressing machine (screw oil press). Each station of palm oil mill uses different methods and machines. After purifying and filtering, the palm oil can be exported as a popular kind of healthy and edible oil. Next I will introduce the production and manufacturing process of palm oil:

Main Machinery for Making Palm Oil:

Sterilizer, Thresher, digester, screw palm oil press, nut/fiber separator and so on.

|

| Palm oil production process flow chart |

Palm Fruit Harvesting Process

The initial process in palm oil mill is reaping the palm fruit bunches.

Palm fruit sterilizing process

Through fruit reception system (left of the above photos), the palm fruit bunches will be transported to the next process - Sterilizing Station.

|

| Palm fruit sterilizer machine |

The sterilization process utilizes steam or water to sterilize the fresh palm fruits. This process likewise stops enzymatic responses that prompt oxidation and upsets the cells which are found in the mesocarp, so that to improve the oil extraction efficiency and final oil product quality.

Palm fruit threshing process

In the threshing process of palm oil mill plant. The fruitlets are separated from the whole bunches by use of stripper machine. Threshing is generally mechanical in large palm oil mill by use of thresher, which rotates or vibrates to remove the fruits from the bunch.

|

| Palm fruit thresher machine |

Palm fruit digesting process

Before extracting oil, the palm fruits need to be crushed in digester machines. To augment oil yield, the fruit pulp is also warmed in this process.

Palm oil pressing process

After palm fruit digesting process, The pulp is then pressed, which bursts the oil-containing cells, releasing the palm oil. During the palm oil pressing process, the screw palm oil press is the most commonly used palm oil making machine in both small and large scale palm oil manufacturing plant.

|

| Screw palm oil press machine |

Palm Oil Clarification process

The purpose of clarification in palm oil production process is to remove impurities. The final crude palm oil will be storage in bulk in a tank.

Palm kernel recovery process

After palm oil expelling, the solids parts discharged from the screw press is mixture of fiber and nuts. In palm kernel recovery plant, the nuts and fiber are separated by physical means. The nuts are sent to palm kernel crushing and solvent extraction plant to make palm kernel oil, while the fiber is used as biomass fuel in boiler on-site.

The above is the detailed production process of palm oil, if you want to get more information about palm oil processing machine, welcome to contact us!

Contact information:

◆http://www.palmoilextractionmachine.com

◆http://www.palmoilprocessingmachine.com

☏whatsApp/wechat: +86 13526627860

E-mail: palmoil@doingmachinery.com