Henan Glory Oils & Fats Engineering Co., Ltd. is a cooking oil machine manufacturer, which can provide palm oil fractionation plant solutions. Our excellent design process and strong company reputation and customized services have earned us a reputation as a trusted and reliable partner in the industry.

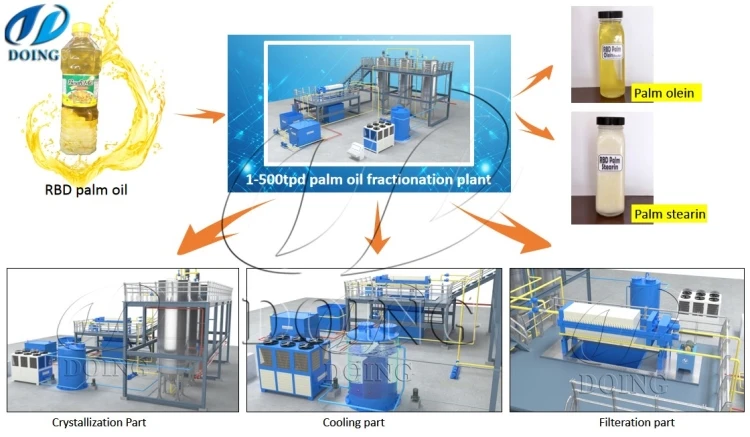

Design Process of Henan Glory Company's palm oil fractionation plant:

Henan Glory Company's palm oil fractionation plant is designed with two crystallization tanks. One tank is utilized to heat the crude oil and melt the crystals in it, ensuring that the quality of stearin and olein is not affected after fractionation. To reduce the temperature of the oil, we use a refrigeration unit to provide frozen water for the crystallization tank. Once the temperature reaches around 5-6 degrees, we filter out the stearin in the oil by pumping it into the filter through the pipeline. A stearin tank is located under the filter to store the hard fat, and the upper part of the stearin tank has blades to divide the stearin into small pieces, preventing it from falling from the filter and damaging the equipment. Our stearin tank also has a heating coil at the bottom, which heats the hard fat into a liquid state, helping the pump to drive the hard fat outside. The filtered olein is then pumped into the outdoor olein tank.

Strength of Henan Glory Company:

We are a large-scale professional cooking oil equipment company with a strong reputation in the industry. Through video call, we can show our company and factory to our customers or customers can choose to have field trips, understanding our expertise and experience in the field. We also can show many of our successful project cases, building trust and confidence in our ability to provide customized services.

Customized Services from Henan Glory Company:

At Henan Glory Oils & Fats Engineering Co., Ltd., we provide customized services to meet the specific needs of our customers. We work closely with our clients to understand their requirements and provide tailored solutions that meet their unique needs. Our team of experts is always available to provide technical support and guidance throughout the entire process.

Contact information:

My Whatsapp/Wechat: +86 13526627860

Website: http://www.palmoilextractionmachine.com

Email: market@doinggroup.com