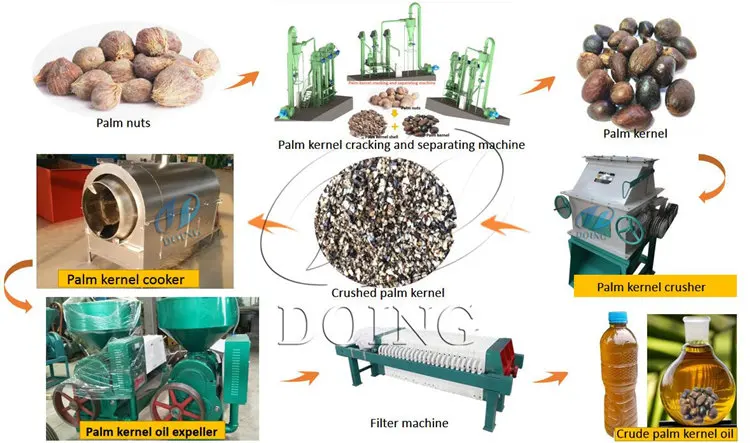

Introduction of 1-10tpd small scale palm kernel oil processing machine:

Palm kernel accounts for 6.5% of palm fruit bunches, and the oil content rate of palm kernel is about 50-55%, also, the palm kernel oil can be used to process various products such as chocolate and margarine etc. So there is a hugh market behind palm kernel oil processing, our company has professional engineers who are good at the designing and developing of palm kernel oil processing machine, our palm kernel oil processing machine includes cleaning, cooking, pressing and oil filtration. After this, you will get crude palm kernel oil which can be sold or deeply processed.

|

| Small scale palm kernel oil processing machine |

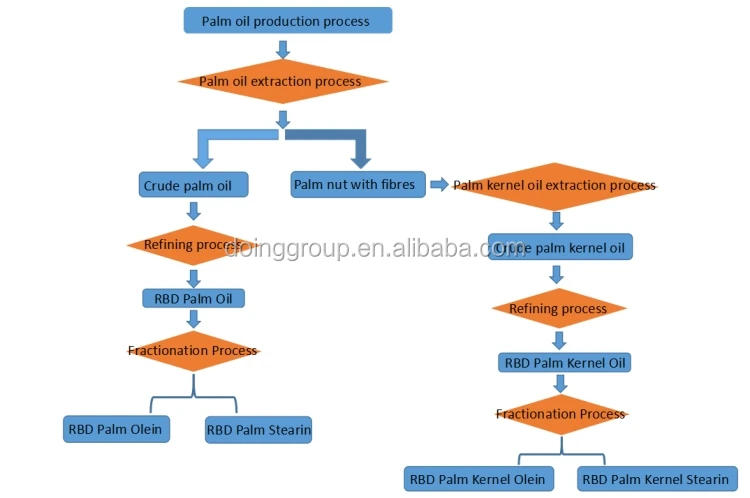

Palm kernel oil processing machine process flowchart:

Contact infromation:

Palm kernel(with shell)--Husking--Cooking--Pressing--Filtration--Crude palm kenel oil&cake

|

| Palm kernel oil processing process |

1, Palm kernel cracaking and separating machine:

if the raw material palm kernel is with shell, first you need to remove the shell. We have specific palm kernel cracking&separating system which can separate the kernel and shell very cleanly. After crushing the palm nut, the shell and kernel weight is very close; to separate it is a very complicated process; we adopt professional palm kernel cracker, Then use air separator system, through adjusting the transducer to control high pressure air speed and volume.

|

| Small scale palm kernel cracaking and separating machine |

2. Palm kernel cooker machine:

the main function of this part of pam kernel oil processing machine is wetting , heating, cooking and drying the the flakiness, the effectiveness of the cooking will affect the oil out rate and the quality of the meal.

|

| Small scale palm kernel cooker |

3. Palm kernel oil expeller machine:

since palm kernel is hard and strong, it needs speicial palm kernel oil press machine which has powerful drive and pressing bolt.Our palm kernel oil press machine are especially designed for pressing palm kernel oil.

4. Palm kernel oil filter machine:

after pressing by the palm kernel oil press machine,there will be some solid impurities in the crude oil, we can use the plate filter to remove most part of the impurities. If you want to get higher degrade palm kernel oil, you can choose to refine it.

Specification of small scale palm kernel oil processing machine:

Number

| Item | Power | Remark |

| 1 | Cooker | 3.0kw |

Heat by biomass or electricity, automatic in and out

|

| 2 |

Palm kernel oil presser

| 30kw |

Professional CPKO press machine, low oil residue and high efficiency

|

| 3 |

Oil filter

| 1kw |

Filter the crude oil.

|

http://www.palmoilextractionmachine.com

http://www.palmoilprocessingmachine.com

whatsapp/wechat: +86 13526627860

Email: palmoil@doingmachinery.com