|

|

| palm fruit oil production line |

|

Palm oil pretreatment process is quite different from other oil seeds processing, such as the soybean , peanut etc. Palm fruits consists a lot of fatty acid enzyme, which would hydrolyze palm oil. That's the reason why palm fruit must be sent into processing in 24 hours.

Palm oil pretreatment process includes 6 parts: Palm bunches receiving, sterilizer, threshing, mashing and pressing, crude oil clarifying and palm kernel recovery.

1.

Palm oil pretreatment process of fruits receiving: Collecting the ripe fresh cluster from the orchard and convey by trucks, then pour the fluster into the discharge door after weighed by ground weighed . The discharge door has discharging channels, the upper and lower switches of the iron gate are controlled by pneumatic, Pneumatic control system consists of air compressor and pneumatic control devices. Start the control valve to open the gate of the discharge door, then the palm fruits will fall into the fruit basket car or conveyor.

2. Palm oil pretreatment process of sterilizer: Fresh palm fruit bunch are airtight sterilized in sterilizer, injecting direct steam (the pressure is 300KPa) to heat 60mins. The purpose is to prevent enzymes broken down, avoiding FFA content in oil further increase.

3.

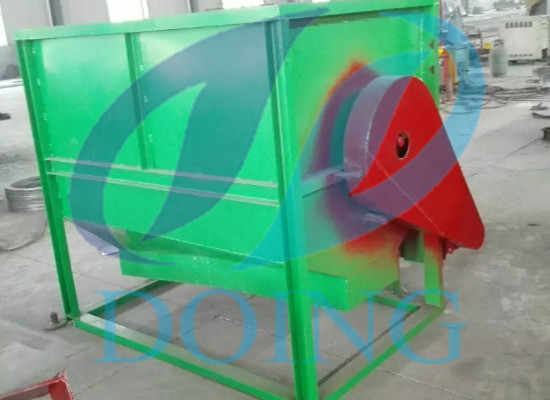

Palm oil pretreatment process of threshing: The purpose of threshing is to separate the palm fruit from the FFB. The drum type thresher is the usual machine to separate the fruit. The separated oil palm fruit is sent into the pressing section. Empty fruit bunch be ejected to the yard from the other side of the revolving drum, or shipped out from the plant as palm orchards slipcover to recycling use, or burning in the locale as fertilizer for agricultural land.

|

| palm fruit oil threshing machine of palm oil pretreatment process |

4. Palm oil pretreatment process of mashing and pressing: There is also the steam heater in masher. The purpose of mashing is to separate the pulp and nut and crush the palm pulp.

At the same time, the steam is used to cook the palm fruit and broke the cell of pulp. Because of cooking, sterilizing, threshing and mashing made the pulp soft and damage pulp cell structure, the palm pulp becomes soft and cell is broken. Then it is sent to continuous screw press. After pressing, oil palm fruit is divided into two parts: the mixture of oil, water and solid impurities, and the press cake (fiber and nut).

|

| palm fruit oil press machine of palm oil pretreatment process |

5. Palm oil pretreatment process of oil clarifying: Machine-pressed crude oil first diluted with water washing, through settlement and filtration, the fiber material removed from the oil, and then carry out continuous settlement, the whole divided into two parts: oil and sediment. Oil by centrifugal separation and through vacuum drying pumped into the storage tank for storing; oil sediment by filtration and dirt oil separation, oil process second settlement, dirt oil mixture process clarification separation, Skim oil then carry out a second settlement, sewage pumps to sewage treatment pond for dealing with.

6.

Palm oil pretreatment process of palm kernel recovery: Press cake broken by breaking screw conveyor and then transported into the fiber separation air net and fiber polishing roller for fiber separating. The separated fiber material is sent to the boiler room as fuel; the separated stone is transported to stone warehouse by pneumatic conveying system for temporary storage.

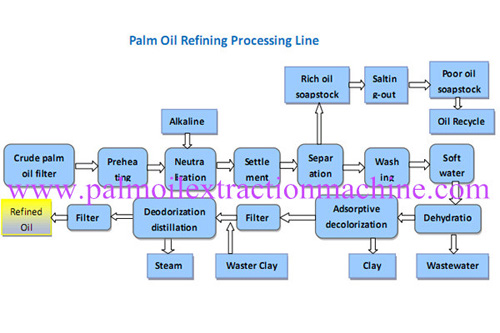

The above are the main sections of

palm oil pretreatment process, if the final users plan to produce the refined the palm oil, the further processes are required.