Introduction of crude palm oil refining machine process:

The process of vegetable oil refining is to refine the crude edible oil, to remove gossypol, protein, phospholipid, grume, moisture and other impurities, in order to reach the purchase of food and storage.

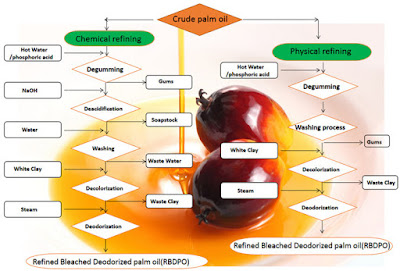

According to different raw materials, the process of cooking oil refining includes mechanical refining method, chemical refining method and physical refining process refining process.

[Related reading: Palm oil refining methods: chemical refining and physical refining ]

[Related reading: Palm oil refining methods: chemical refining and physical refining ]

Main process of the refining:

1. Crude Cooking oil degumming process,

2. Crude Vegetable oil deacidification/neutralization process

3. Crude Edible oil decoloring process

4. Crude cooking oil deodorization/distillation(deodorising unit) process

The application scope of Palm oil refining machine:

Various kinds of crude cooking oil refinery, like Crude soybean oil refining, crude sunflower oil refining, crude peanut(groundnut) oil refining, crude rapeseed oil refinery, CPO refining, crude rice bran oil refining, crude corn oil refining and other crude edible oil refinery.

1.Introduction:

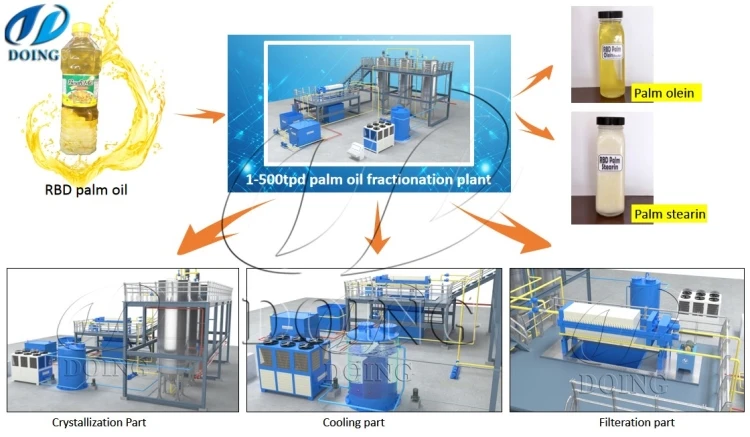

(1) Crude oil refining workshop is through take off impurity, Degumming, decoloring, deodorization, removing wax, fractionation etc, to achieve different standards edible oil.

At present, Having four grade of edible oil, different oil grade have different requirement for quality and machines.

It is suitable for refining various crude vegetable oil, such as sunflower oil, tea oil, groundnut oil, cottonseed oil, palm oil, rice bran oil, soybean oil, corn oil and palm oil, etc.

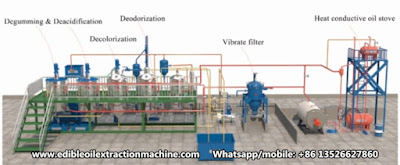

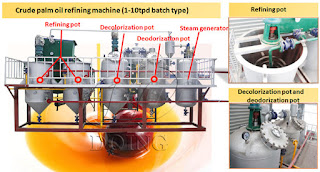

(2) Main parts:refining pot , decoloration pot ,deodorization pot , oil pumps and other parts

(3) Advantage: 1.After refining the impurity of oil must be less than 0.2%;

2. Recycling system save power and money;

2. Working process:

(1)Pump crude edible oil into refining tank and heat with conduction oil, and the temperature will reach about 70°C-80°C after one hour.Add acid or alkali to separate according to the acid value. After one hour's processing and 4-6hours deposit, then convey soap stock to storage tank.

(2)Pump refined oil into decoloring tank. When it is up to 90-110°C after one hour's heating, add clay into tank for 20min's processing. Then separate clay and oil with filter.

(3)Put decolorizing oil into deodorization tank with vacuum pump. Heat and process with steam for odor removal. After filtering, you will get final oil product.

[Related post: Small scale palm oil refinery plant]

[Related post: Small scale palm oil refinery plant]

3.Functions of main parts

(1) Refining section: used to P-acid de-gumming, alkali refining de-acid and water rinsing.

(2) Decoloring section: used to remove off pigments, bleaching oils and grease dehydrate.

(3) Deodorizing section: to remove off the odor components in oil.

(4) Dewax: used to remove off the wax in the oil, in order to get the high quality oil.

http://www.edibleoilextractionmachine.com

whatsapp/wechat/mobile: +86 13526627860

Email: oilmachine@doinggroup.com