Our

company is professional in manufacturing palm oil mill plant for years.

We can offer the full palm oil production line and turnkey project.The

complete palm oil mill plant include palm oil press production line

,palm kernel oil press production line and palm oil refining production

line .

|

| Palm oil press production line |

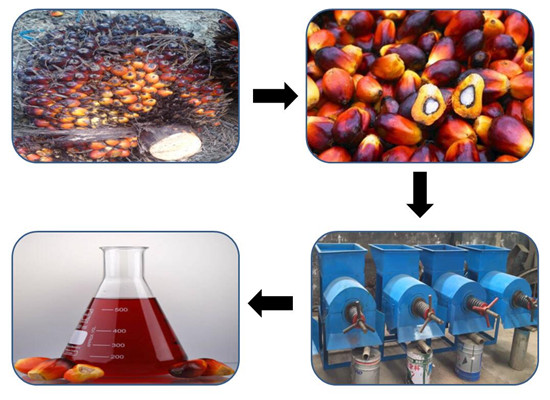

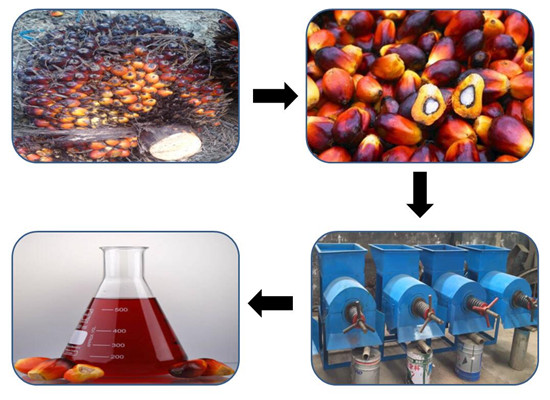

1. Raw materials reception and storage

Workers

pick fresh fruit bunches (FFB) , transport them to factory with cars,

get the weight by Loadometer and discharge them to material platform

which is specially designed for crude palm oil processing, laying up for

latter process. Open the gate of discharging platform, FFB would fall

down to the conveyor automatically and be sent to sterilizing section.

2.Sterilizing section

The function of sterilizing, known as

stewing in high temperature, is to avoid the deterioration of fruit.

This section can avoid the increase of palm oil AV by stewing the fruit

about 60min with 300kPa steam in a specialized sterilizer.

3. Threshing section

The palm fruit proportion is about 60% of

the FFB. In this section, we always use rotating drum thresher to

separate palm fruit from the bunches.

4. Crashing

The purpose of crushing is to destroy palm

skin, separate the palm pulp and nuts, pound palm pulp and to damage

the cell structure of palm pulp by heating at the same time, which avail

the latter pressing section.

5. Pressing

In crude palm oil processing, screw oil

press is common equipment we use, the outcome of which is mixture of

water, oil &residue and presscake (fiber cake).

6. Crude palm oil

Separate

the fiber from the mixture derived from pressing by subsidence and

filtration, after continuous subsidence we can separate oil and

precipitate. With another filtration and vacuum drying, the oil is just

crude palm oil as we say.

Other information:

Skype:sophia.zang1

Mobile:+86 158 3826 3507

Phone:+86-371-5677 1823

Website:www.palmoilextractionmachine.comhttp://www.doingoilmachine.com

E-mail: palmoil@doingmachinery.com